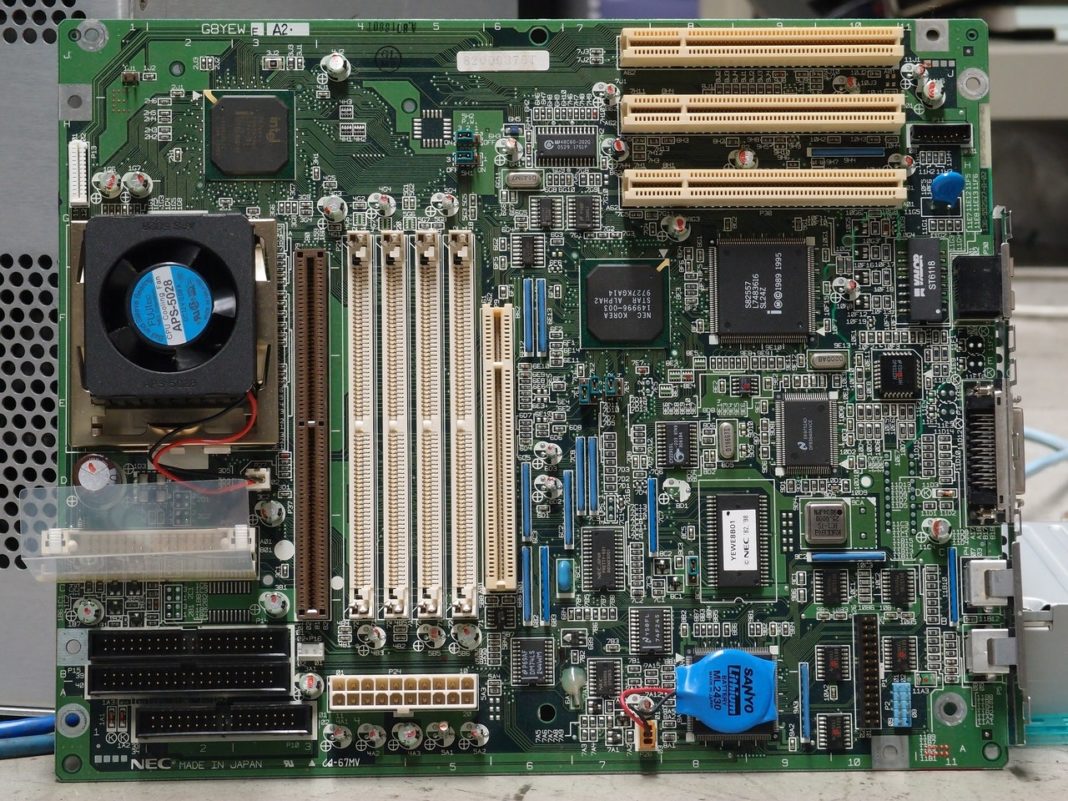

The printed circuit boards assembly (PCBA) process is a complex one, but it’s also an essential one. If you’re not familiar with PCBA, it’s the process of soldering and attaching electronic components to a PCB. This can be a daunting task, but it’s important to understand the process if you want your PCBs to function properly. In this blog post, we’ll take a closer look at the PCBA process and discuss some of the key steps involved in it.

PCB Design Basics

When it comes to PCB design, there are a few things you need to keep in mind if you want to create a high-quality circuit board. First and foremost, you need to make sure that your PCB layout is as simple and straightforward as possible. This means keeping the trace lengths short and avoiding any unnecessary turns or bends. Additionally, you need to be aware of the different PCB stack-up options available to you and select the one that best meets your needs. It’s always nice to have PCB Assembly Quotes. Finally, pay close attention to your solder mask and silkscreen layers to ensure that they are legible and accurate. By following these simple tips, you can be confident that your PCB will meet your expectations.

Actual PCBA process steps

Printed circuit board assembly, or PCB assembly, is the process of connecting electronic components to a printed circuit board. PCBs are found in all kinds of electronic devices, from computers and cell phones to appliances and automobiles. The PCB assembly process can be broken down into four main steps: design, fabrication, assembly, and testing.

Designing a PCB is the first step in the PCB assembly process. This is where engineers decide what components will be used and how they will be connected. The design must take into account the size and shape of the components as well as the desired electrical characteristics of the finished product. Once the design is complete, it is sent to a fabricator who produces the actual PCB.

The next step in PCB assembly is fabrication. This is where the PCB is actually made. The fabricator creates the PCB using a process called photolithography. First, a layer of copper is deposited on a substrate material such as glass or plastic. Next, a photographic mask is placed over the copper and exposed to ultraviolet light. This causes the exposed areas of the copper to etch away, leaving behind the desired circuit pattern.

After the PCB has been fabricated, it is time for assembly. This is where the components are attached to the PCB. There are two main methods of component attachment: through-hole and surface-mount. In through-hole assembly, components are inserted into holes in the PCB and soldered in place. Surface-mount assembly uses tiny pads on the PCB to hold the components in place. Components are then soldered to these pads.

The final step in PCB assembly is testing. This is where engineers test the PCB to make sure it meets all the design specifications. They may use a variety of methods, including visual inspection, electrical testing, and X-ray inspection. Once the PCB has passed all tests, it is ready for use in electronic devices.

PCB assembly is a complex process, but understanding the basics can help you get started on your next project. So take some time to learn about PCBs and how they are made.

After PCBA

After the PCB design is completed and all of the components have been placed, it’s time to start thinking about PCB assembly. This is the process of connecting all of the components to the PCB and making sure they are properly soldered. There are a few different methods of PCB assembly, but the most common is through-hole soldering. This involves placing the component leads through holes in the PCB and then soldering them in place on the other side. SMT (surface mount technology) components are also becoming more popular as they are much smaller and can be placed directly on the surface of the PCB.

PCB assembly can be a tricky process, especially if you’re working with a lot of small components. It’s important to have a steady hand and to be very careful not to damage any of the components or the PCB itself. It’s also important to make sure that all of the connections are properly soldered and that there are no shorts between any of the leads. Once you’ve completed the PCB assembly, you should have a fully functioning circuit board that is ready to be used in your project.

The PCB assembly process is just one part of creating a working circuit board. You also need to design the PCB layout, which includes placing all of the components in their proper places on the PCB. This can be done with a CAD (computer-aided design) program or by hand if you’re feeling adventurous. Once you have placed all of the components on the PCB, you need to connect them together with copper traces. These are the conductive pathways that allow electricity to flow from one component to another. The PCB layout will also include vias, which are small holes that allow the traces to pass through different layers of the PCB.

After the PCB layout is complete, you’ll need to print it out on a piece of paper or transfer it to a substrate material. This is usually done by etching the PCB layout onto a sheet of copper-clad board and then removing the unwanted copper with chemicals or abrasives. Once the PCB is etched, you can drill holes in it for through-hole components and add any solder masks or silkscreens that you want.

SMT and THT

Both SMT and THT have their own advantages and disadvantages, so it’s important to select the right type of assembly for your particular project. For example, SMT is generally faster and more cost-effective than THT, but it can be more difficult to repair if something goes wrong. THT, on the other hand, is slower and more expensive, but it’s much easier to fix if there are any issues. Ultimately, the best way to decide which type of PCB assembly is right for you is to consult with a professional PCB manufacturer.

Now that you know how PCB is made, you can start thinking about how to design your own PCB. Remember to keep the PCB assembly process in mind as you design so that you can make sure your PCB will be easy to assemble. You can also use a PCB fab service to have your PCBs made for you if you don’t want to go through the hassle of making them yourself. Either way, once you have your PCBs, you’ll be able to start working on your next electronic project!