In recent years, Presstonic Engineering has emerged as a groundbreaking technology that is revolutionizing multiple industries. This innovative field combines principles of precision engineering and electronics to create devices and systems that are more efficient, accurate, and reliable than ever before. By utilizing precise control mechanisms and advanced sensors, Presstonic Engineering has the power to significantly improve processes across various sectors, from manufacturing to healthcare to aerospace.

The Rise of Presstonic Engineering

Presstonic Engineering represents a paradigm shift in how machines and devices are designed and operated. Traditional engineering approaches often focused on mechanical components, with limited integration of electronic systems. However, Presstonic systems leverage the latest advancements in sensors, actuators, and control algorithms to achieve unprecedented levels of precision and control.

Applications in Manufacturing

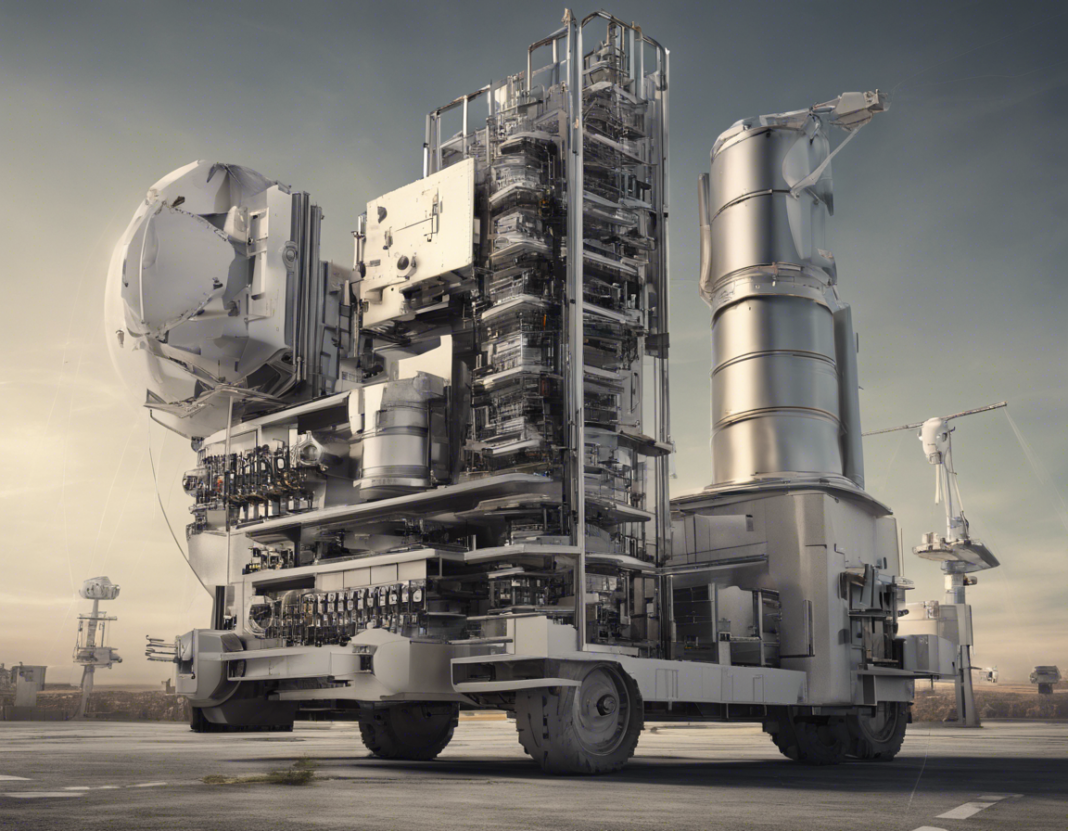

In the manufacturing industry, Presstonic Engineering is being used to optimize production processes, enhance product quality, and increase overall efficiency. By incorporating real-time monitoring and feedback mechanisms, manufacturers can fine-tune their operations to reduce waste, minimize errors, and streamline workflows. From automated assembly lines to robotic machining systems, Presstonic technologies are transforming the factory of the future.

Advancements in Healthcare

In healthcare, Presstonic Engineering is revolutionizing diagnostic imaging, surgical procedures, and patient monitoring. For example, advanced medical devices equipped with Presstonic systems can deliver precise doses of medication, perform minimally invasive surgeries with unparalleled accuracy, and provide continuous monitoring of vital signs. These applications not only improve patient outcomes but also enhance the capabilities of healthcare professionals.

Impact on Aerospace

The aerospace industry has also embraced Presstonic Engineering to enhance the performance and safety of aircraft and spacecraft. By integrating sophisticated control systems, such as fly-by-wire technology and autonomous navigation, aerospace engineers can design aircraft that are more maneuverable, fuel-efficient, and resilient to external factors. As a result, Presstonic technologies are driving innovation in aviation and space exploration.

Key Benefits of Presstonic Engineering

- Enhanced Precision: Presstonic systems enable sub-micron accuracy and nanosecond response times, leading to higher levels of precision in various applications.

- Improved Efficiency: By optimizing control algorithms and feedback loops, Presstonic Engineering can significantly increase the efficiency of processes and systems.

- Greater Reliability: The integration of advanced sensors and actuators enhances the reliability and robustness of Presstonic devices, reducing the risk of failures.

- Enhanced Flexibility: Presstonic systems are highly versatile and adaptable, allowing for quick adjustments and reconfigurations as needed.

Future Outlook

As the capabilities of Presstonic Engineering continue to expand, the potential applications across industries are limitless. From smart infrastructure and autonomous vehicles to robotic prosthetics and environmental monitoring, the impact of Presstonic technologies will only grow in the years to come. By harnessing the power of precision engineering and electronics, we are advancing towards a future where complex systems can operate with unprecedented levels of accuracy, efficiency, and reliability.

Frequently Asked Questions (FAQs) about Presstonic Engineering

-

What is Presstonic Engineering?

Presstonic Engineering is a field that combines precision engineering principles with electronics to create systems with advanced control mechanisms and sensors. -

How is Presstonic Engineering different from traditional engineering?

Unlike traditional engineering approaches that focus primarily on mechanical components, Presstonic Engineering integrates electronic systems for enhanced precision and control. -

What industries can benefit from Presstonic Engineering?

Industries such as manufacturing, healthcare, aerospace, and many others can benefit from the advancements in Presstonic Engineering. -

What are some real-world applications of Presstonic Engineering?

Some examples include automated manufacturing processes, precision medical devices, and advanced control systems in aerospace. -

How does Presstonic Engineering improve efficiency in processes?

By incorporating real-time monitoring and feedback mechanisms, Presstonic Engineering optimizes processes to reduce waste and errors, leading to increased efficiency. -

What are the key benefits of using Presstonic systems?

Key benefits include enhanced precision, improved efficiency, greater reliability, and enhanced flexibility in operating various systems and processes. -

What advancements are expected in Presstonic Engineering in the near future?

Future advancements may include even higher levels of precision, increased integration with artificial intelligence, and expanded applications in emerging technologies. -

How can companies implement Presstonic Engineering in their operations?

Companies can work with specialized engineering firms or develop in-house capabilities to design and integrate Presstonic systems into their existing infrastructure. -

Is Presstonic Engineering only suitable for large corporations, or can small businesses also benefit from it?

While large corporations have been early adopters of Presstonic Engineering, small businesses can also benefit from the improved efficiency and precision offered by these technologies. -

What role will Presstonic Engineering play in the Fourth Industrial Revolution?

Presstonic Engineering is expected to play a critical role in the Fourth Industrial Revolution by enabling advanced automation, data-driven decision-making, and enhanced connectivity across industries.